The Duravant family of operating companies serve the food processing, packaging and material handling segments.

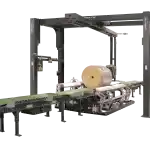

Wulftec’s fully automated In line top sheet applicator.

To retrofit an automatic in line top sheet dispenser unit with its own conveyor section, in a conveyor line or over an existing conveyor section.

The unit is supported by an overhead port structure straddling an extra heavy-duty powered roller conveyor section.

The top sheet unit features auto height sensing device, bottom film loading, double chain driven vertical motion, lack of top sheet alarm light, 60″ to 72″ top sheet roll width capacity, top sheet up/down manual mode, and load flow control photoeyes.

The unit comes with its own controls and with dry contact communications to link with the other conveyor system.