The Duravant family of operating companies serve the food processing, packaging and material handling segments.

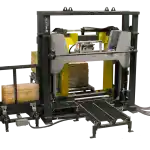

The LMB-250 Lumber Press is specifically tailored to the LUMBER and Panel Industries. The hydraulic compression strapping system design facilitates maintenance and operation. Top and side compression ensures stable, tight loads that will retain high tension during transportation. The LMB-250 Lumber Press is easily integrated into existing production lines to create a seamless packaging system.

Brochures

Wulftec Brochure - Lumber PressAre you interested in this product? We are here to help.

Videos

Features

- Wulftec was the first in North America to put AC variable frequency drives as standard equipment on all machines. Why? Lower maintenance and better reliability—Wulftec equipment will save time and money

- NEMA 4/12 control panel dust tight and waterproof

- The control panel is neatly organized eliminating time otherwise lost searching for wires

- The control panel is UL508A approved

- Superior Electrical/Electronic Design including Allen Bradley Micro800 Series and AC drives

- User friendly touch screen offers a simple yet effective way to adjust and maintain your equipment

- All motors, proximity sensors, photoeyes and other sensors have quick disconnect cables that simplify installation and maintenance

- Photoeyes are maintenance free and protected

- All Wulftec structures are made of heavy-duty steel for rugged performance, even in the harshest work environments. They’re built to last forever

- During the strapping cycle, the strapping head indexes towards the load before tensioning sequence, so tensioning and sealing are done against the side of the load.

- The strapping head is mounted on a movable assembly guided through linear bearings, and activated by an electric motor with a timing belt. The head has a load sensing device that detects the side of the load and tells the head movement to stop so tensioning and welding are done as close as possible to the product for maximum strap containment efficiency.

- The bottom section of the strapping arch can be a standard undertrack style or an electric motor driven pallet bayonet for “through-pallet” strapping or a combination of both.

- Up to 8 straps per minute may be applied, depending on strapping arch and package dimensions, strap quality and strap tension required.

- Electronic tension control through a variable frequency drive. Assures consistent tension control regardless of the number of cycles and environmental conditions. The strap tension is adjustable from the touch screen.

- Our heavy duty conveyors are second to none in the industry

- Coils of PET strapping with a core diameter of 16″ can be fitted to the high speed dispensers, with pulley block accumulation system and electrical brake.

- Non-Proprietary parts accessible on a local base

- The best warranties in the industry

- 1-year on the strapping head and track

- 3-year unlimited cycle warranty

- 3-years on the steel structure

Key Specs

Key Specs

Machine Dimensions

- 58 " L x

- 130 " W x

- 131.5 " H

Approximate Shipping Weight

- 10000 lbs

- Excluding optional bunk feeder and conveyors

Minimum Load Size

- 32 " W x

- 15 " H

Maximum Load Size

- 58 " H

- 60 " W x

Maximum Load Weight

- 5000 lbs

- 6000 lbs

Electrical Requirements

- 460 V /

- 3 ph /

- 60 Hz

- 40 A

Pneumatic Requirements

- 3 cfm @

- 80 psi

Controls

- Allen Bradley CompactLogix L24 PLC

- Allen Bradley PanelView Plus 600 monochrome Touch Panel

- 24V control system

- Current overload protection

- NEMA 4/12 control cabinet with quick disconnect

- Sick autoheight sensing photoeye with on/off mode

- Power on/off lockable switch and indicator light

- 460VAC motors & variable frequency drives

- Allen BradleyPowerFlex 525

- Two emergency stop stations (1 on panel / 1 on platen)

- Manual function for platen up/down and conveyor fwd/rev

- Variable compression settings

- Intuitive alarms diagnostic on touch screen

- Machine and head cycle counters

- Reset function

- Strap track with under track allowing under pack strapping

- 2 fully adjustable strapping patterns

- Alarm beacon

- 120 VAC outlet in control panel for service work

Strapping head

- GS41 HT strapping head

- Possibility to strap with polyester from 3/8" to 5/8" wide

- Consistently reproducible strap tensioning through an Allen Bradley Powerflex 70 VFD

- Tension control with motor torque monitoring via the drive

- Tension is adjustable on the HMI

- Consistently high seal efficiency

- Environmentally favorable sealing by vibration welding

- Separate drive section for high speed strap feeding and take up to achieve maximum tension levels

- Electronic strap circulation control

- Accurate tension alignment of the strap

- Precise and quick adjustment by automatic strap feeding unit

Strap dispenser

- Coils of strap with a core diameter of 16" can be fitted to these high speed dispensers, with pulley block accumulation system and electrical brake

- An optional powered version available for jumbo coil

Structure

- Heavy duty folded sheet metal uprights with upper frame structurally integrated with base for greater stability

Top & Side compression

- Hydraulic compression pads for greater consistency and reliability

- Compression controlled with pressure regulator on hydraulic units and pressure switch. Separate regulation for top and side compression

- Compression speed controlled by flow regulator on hydraulic unit

- Side compression using an oversized dual rack and pinion equalizer system

- Maximum compression up to 25 000 lbs

Safety Features

- Maintenance safety pin to block the platen in place. This pin, when inserted, activate a sensor preventing the machine operation

- 2 E-Stop mushroom type push buttons: 1 on control panel, and 1 on the platen

Conveyor

Technical Information

- The machine is provided with a manual including electro/mechanical schematics and drawings, maintenance program and PLC program disk

* Options