The Duravant family of operating companies serve the food processing, packaging and material handling segments.

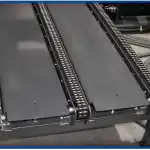

Why choose a Chain Conveyor system? Because, their surface is flat and smooth; the load is moved from one end to the other without any jolt or vibration. Ideal for glass bottles, PET bottles, cans and other fragile materials. They are easy to clean and maintain. They meet the food, beverage industry’s requirements for hygiene.

Brochures:

Heavy Duty ConveyorsAre you interested in this product? We are here to help.

Videos

Features

- State-of-the art construction:

- 2, 3, 4 or 5 strands are available

- All chain strands are dual #60 chains

- Maintenance free cast iron housing sealed bearings

- Adjustable structural steel leg assemblies

- Interchangeable feet to allow pass height changes

- Safety fall space cover plates

- All chains are powered by one gearbox for a perfect synchronisation

- Chains are driven from the middle of the conveyor for optimum forward and reverse use

- Each chain strand is individually adjustable

- 5,000 lbs capacity

- Best warranty in the industry (3 years)

- Adjustable drive system:

- Easy to adjust without guard removal

- Easy access from top of conveyor

- Drive unit mounted below conveyor guard for more protection

- Synthetic gearbox lubrication

- All quick disconnect wiring for easy installation & maintenance

- 1 HP – 230 / 460 VAC TEFC motor

- 30 FPM, up to 60 FPM available

- Versatility:

- 24 VDC components

- Non-proprietary parts throughout

- Variety of lengths, widths and heights available

- Many available options

Key Specs

Key Specs

Machine Dimensions

- 60 " L x

- 18 " H

- Other size availables

Maximum Load Weight

- 4000 lbs

Controls

- Allen Bradley PowerFlex 525 drive, 230VAC / 3A / 60Hz

- Sick #WT11-P430 background suppression photoeye

- NEMA 4/12 junction box with PVC pipes

Conveyor

- 3 strands of double #50 chain – 17" center to center

- 2, 3 or 5 strands are available

- 60 fpm

- Baldor 230-460VAC / 3A / 60Hz 1.5HP

Warranty

- 1 year

* Options